Plastic you can work with. Here's how.

• Cutting the duct

• Cutting the plank

• Bending the duct

• Drilling the plank

• Smoothing the edges

• Gluing

Cutting Tastic Plastics

Tastic plank cuts easily with a power saw, like a circular saw or hand held jig saw, or in the shop we use a table saw or band saw. Hand saws don’t work very well as they tend to bind or else the plastic wobbles and is difficult to hold steady.

The plank is pretty strong. You can cut it with big tin snips or aviation shears (also called combination shears). If a hand cut doesn’t come out perfect, you can sand the edge or use a surform plane to make it smooth and straight.

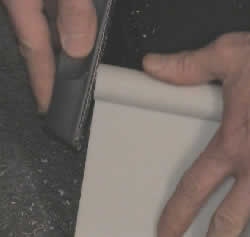

Tastic duct is thin and springy. It can be cut with a strong pair of scissors, or shears, or snips.

We have used a rotary tool (similar to Dremel) with a cutting spindle or a cut-off disk, but found it is difficult to get straight cuts when hand held. It works best if we use the Dremel cutting kit (shown here) and run it along a straight edge, or any of the Dremel router adapters.

You can put Tastic Plastics on a CNC cutting machine, but don’t use it with a laser. Laser vapors off PVC can be dangerously corrosive.

Bending Tastic Plastics

Warm Tastic duct to make it soft. Use a hair dryer, or 10 seconds with a heat gun and it becomes bendable. A little hotter and duct material becomes totally limp. No need to get any hotter which might risk discoloration. We also have success using a hair curling iron. Small pieces get limp as a wet noodle when you dunk them in boiling water, then shape them and cool them and they make new memory. Once cooled Tastic duct holds the new shape with the full force of its springy resilience.

The plank can also be bent but bends are a little less precise, and the extra heat needed to bend the tough plank risks scorching which can discolor it.

Use gloves to protect your hands when holding hot plastic, waiting for it to cool.

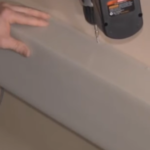

Drilling Tastic

Drilling is super easy using a drill or an electric screwdriver. A conical step drill bit can be used to make the hole any size you like. You can also use a hole saw.

Gluing

Tastic Plastics are formulated to glue great with PVC cement. It actually glues better than PVC pipe, so you don’t need to use primer, just a thin coat of the clear PVC cement applied to both surfaces, then clamped. Don’t use the heavy duty type of PVC cement; it’s too thick. You want a thin coat so you can get good surface-to-surface contact when you clamp them together. It sets in about 3 minutes, and gets stronger for about 10 minutes.

Hot-melt glue holds great, if you work it into the surface. Use the tip of the glue gun to get the surface of the Tastic heated up.

Welding and melting

Small welds can be done with a small tip at 580 deg F. That’s the temp of many cheap soldering irons. You can tack-weld two pieces by poking a soldering iron straight through.

The trick to welding plastic is to add new plastic and work it into the pieces to be bonded. But you get similar results doing the same thing with the hot tip of a hot-melt glue gun, introducing the glue as the new plastic and work that into the Tastic.

Taping, riveting

Often the attachment you want is as simple as tearing off a piece of tape. Thin double-stick carpet tape works great. Duct tape and packing tape hold great. One trick when using duct as a cover over plank is to tape it on the inside, so the cover swings up like a hinge, and as it drops down the geometry of the side channels pulls the cover tight to the wall.

We have great results with the thick, rubbery nano gel tape. 4 little squares can mount a panel to the wall or to furniture. To release nano tape, grab a corner and stretch it.

Tastic is strong enough to hold rivets, screws, and of course, you can secure pieces with a zip-tie.

Painting and covering

Some spray paint says it is made for plastic but we have found that any spray paint works just as well, as long as you apply thin coats. Latex house paint covers easily.

We also use peel-n-stick covering such as contact paper, or faux leather vinyl.

Snap together

It’s very effective to cut a slot in one piece, carve a tab in another, and join them to construct things like barricades or aquaducts or vertical gardens.

One design is to bend tabs inward on a cover, then hook those behind the plank’s curved side channels.